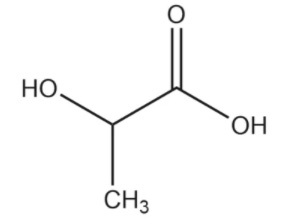

Lactic Acid

Lactic Acid Material Introduction

Introduction to the application of the Company's lactic acid products - L-lactic acid

Lactic acid product category

Technical features and advantages

1. The use of dual enzyme technology and a new generation of lactic acid bacteria reduces the sugar production and fermentation cycle while significantly improving the sugar-acid conversion rate and optical purity of lactic acid.

2. Jointly develop internationally advanced decolorization, membrane filtration, evaporation and purification technologies to significantly reduce energy consumption and increase lactic acid yield.

L-lactic Acid Product Specifications

Standard: GB 1886.173-2016 Packaging Specifications: Food-grade polyethylene barrels, 25 kg/barrel, 250 kg/barrel, and other specifications, packaged according to customer requirements.

| Project | Unit | Index |

| Lactic acid content | W/% | ≥98 |

| L-lactic acid as a percentage of total lactic acid content | W/% | ≥98 |

| Ignition residue | % | ≤0.05 |

| Chloride (as Cl) | ppm | ≤10 |

| Sulfate (as SO4) | ppm | ≤20 |

| Iron salt (as Fe) | ppm | ≤5 |

| Cyanide | mg/kg | ≤1 |

| Citric acid, oxalic acid, phosphoric acid, tartaric acid | / | By experiment |

| Reducing sugar | / | By experiment |

| Carbonaceous compounds | / | By experiment |

| Chromaticity | APHA | ≤20 |

| lead | mg/kg | ≤2 |

| arsenic | mg/kg | ≤1 |

Manufacturing and Delivery Guarantee

Smart Factory

Comprehensively implement automation and informatization to build a smart factory.

Capacity Guarantee

The annual production capacity of high-quality lactic acid exceeds 75,000 tons.

Service Guarantee

Global coverage, rapid response, meeting the diverse needs of customers. Provide safety inventory reserves for strategic customers.

DCS control room

Leading domestic membrane filtration system

Advanced international separation and purification system

Advanced international separation and purification system