Company Profile

PLIITH Biotechnology Co., Ltd., abbreviated as "PLIITH", was established in May 2021. The Company is based on the "Next-Generation Polylactic Acid (PLA) Industrialization Technology" of Changchun Institute of Applied Chemistry of Chinese Academy of Sciences. Focusing on the PLA industrialization, PLIITH has a full-chain layout for "Biomass - Lactic Acid - Lactide - Polylactic Acid" research, development, production and sales. It is dedicated to providing high-quality green, low-carbon, and eco-friendly products and services, contributing to China’s "3060 Dual Carbon" strategy and the global effort to address "Plastic Pollution."

Incorporate

Foundation laying

Completion

Lactic acid

Polylactic acid

Technology

The PLIITH R&D team is led by Academician Chen Xuesi, a leading figure in the field of biodegradable polymers. The core members of the team have more than 10 years of industry experience and possess extensive experience in industrial development and applications, mastering the core technologies across the PLA industry chain.

The technical team led by Academician Chen Xuesi from Changchun Institute of Applied Chemistry of Chinese Academy of Sciences

Industry technical leader

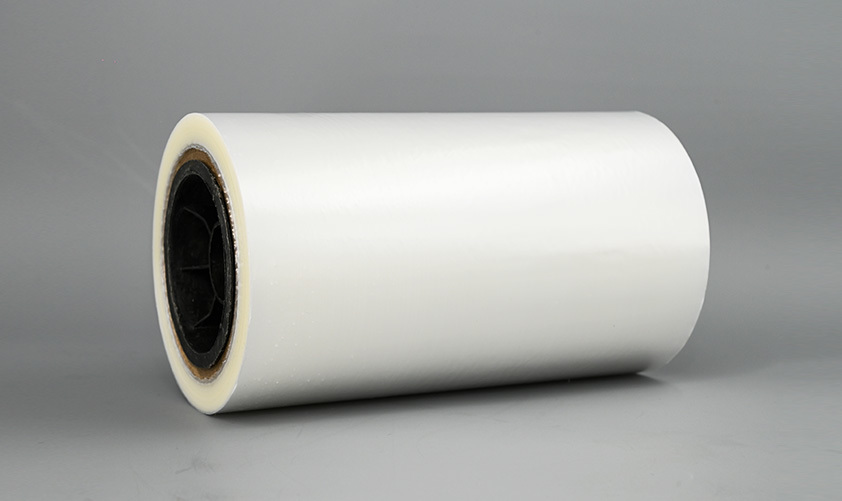

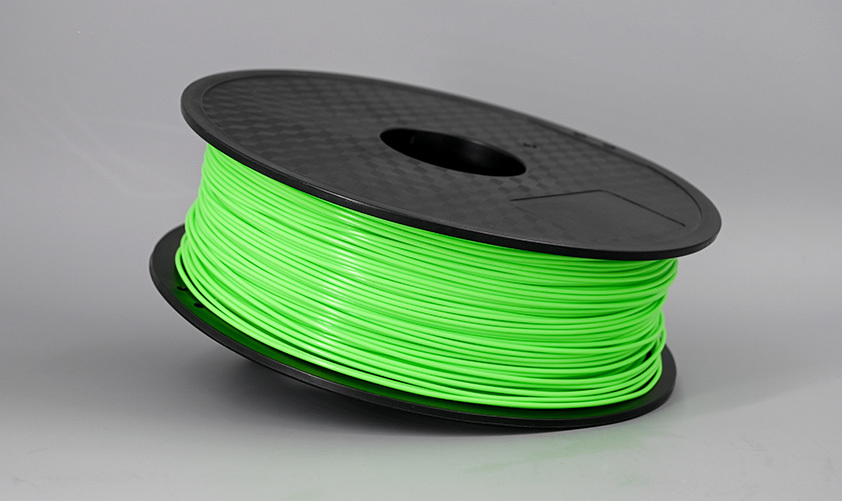

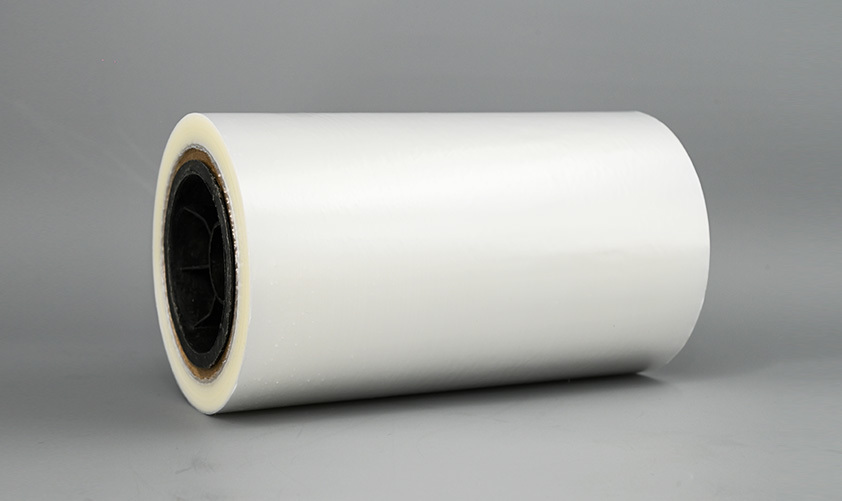

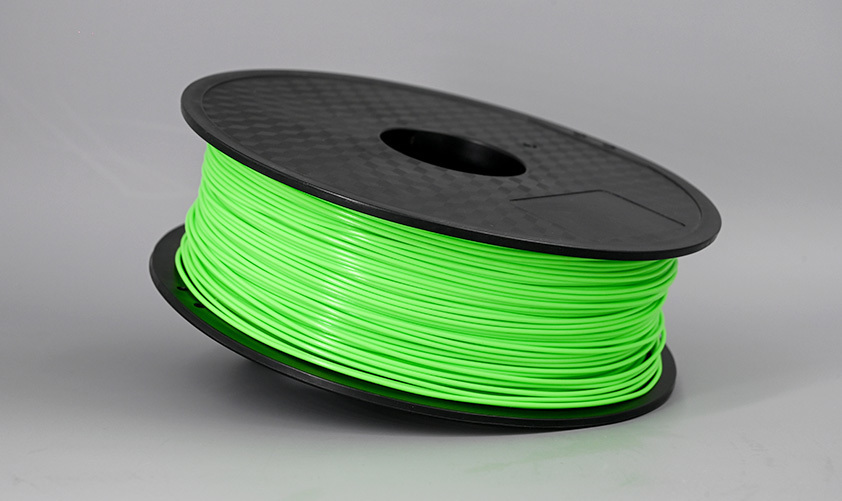

Product Mix

Application

Honor and Qualification

News and Information

TO Be Global Leader in PLA lndustry

Bio-based

Bio-based plastics are distinguished from petroleum-based plastics by the initial source of the material.

Conventional plastics such as polyethylene and polypropylene are derived from petroleum refining, thus classified as petroleum-based plastics. The initial raw materials for PLA and polyhydroxyalkanoates come from plant-based starches or sugars, making them biobased plastics. Depending on whether the initial raw material of a plastic is petroleum-based or biobased, and whether the plastic is biodegradable, existing plastics can be divided into four major categories.

Polylactic acid

PLA is a polyester material and a promising new material among biobased materials.

PLA is a polyester material and a promising new material among biobased materials. Its raw materials come from natural biomass and have fully biodegradable properties. It can be utilized by microorganisms in nature, ultimately producing carbon dioxide and water, with no environmental pollution. PLA exhibits excellent mechanical and processing properties similar to those of existing plastics such as PET and polystyrene. Additionally, PLA has good biocompatibility, being non-toxic and non-irritating. It can be biodegraded and absorbed, and broken down by enzymes or degraded into small molecules and excreted from the body.

Key Features of PLA

The characteristic of polylactic acid is its excellent biodegradability. The biodegradability of PLA allows it to decompose into lactic acid in nature, which then hydrolyzes into carbon dioxide and water. Through photosynthesis, these elements are converted back into starch, forming a natural cycle that promotes ecological balance. Replacing conventional plastics with PLA can address the global issue of white pollution that plagues the world today. It is one of the key paths for global plastic pollution control. Vigorously developing polylactic acid materials is an important guarantee for the successful implementation of the country's "plastic restriction order".

②Biocompatibility: PLA's excellent biocompatibility has led to its widespread application in the biomedical field.

Breakthrough in “Bottlenecks” Technologies

Thanks to over two decades of technological development and industrialization efforts by three generations of scientists at the Chinese Academy of Sciences, the industrialization technology of PLA materials has broken foreign technology monopolies, overcoming "bottleneck" issues and achieving international leadership in the second-generation industrialization technology.

The Changchun Institute of Applied Chemistry of the Chinese Academy of Sciences, as the only research institute in China that has undergone large-scale industrial verification for PLA synthesis technology, has more than 20 years of research, development, and industrialization experience. In recent years, the Institute has conducted in-depth research and development and pilot testing to address a series of key technological and equipment issues in the PLA industry, such as the high-temperature racemization and carbonization of lactide during production, the high energy consumption and low purity in lactide purification, and the difficulties in mass and heat transfer due to the high viscosity of the polymerization reaction system. As a result, the institute has taken a leading position globally in PLA material industrialization process technology.

A model of industry-university-research-application collaboration

The Company has established a cooperative relationship with the team of Academician Chen Xuesi from the Changchun Institute of Applied Chemistry of Chinese Academy of Sciences, and annually invests RMB 10 million in industrialization and applied technology development. At the same time, PLIITH, the Changchun Institute of Applied Chemistry of Chinese Academy of Sciences, and the Wuhu Municipal People's Government jointly build the "Wuhu Biobased Materials Joint Innovation Center", which will comprehensively focus on the technological research and development and industrialization of common technical difficulties, frontier technologies, green manufacturing, and product applications in the biobased materials industry.

Establish a core technology system for the entire industry chain

With lactic acid fermentation, high-purity lactide preparation, and lactide polymerization to produce polylactic acid (PLA) with high chemical purity, high optical purity, and narrow molecular weight distribution as the core technologies, the Company has fully mastered the entire "sugar-lactic acid-lactide-PLA" industry chain technology, achieving domestic and international technological leadership in the field of PLA.

Highly intelligent production line

Achieving fully automated production throughout the process, the project's production line has the capability to produce multiple grades on a single line, allowing for switching between resin grades based on production schedules. The production line can also achieve online addition of corresponding catalysts and additives, reducing human interference, resulting in higher efficiency, better product quality, and greater stability.

Profound technical reserves

Deployments have been made in areas such as the development of efficient compound catalytic systems, new methods for lactide synthesis, rapid crystallization PLA resins, and special resins for stereocrystalline PLA, forming a multi-level technical reserve that will accumulate and deliver significant results.

The total investment in the PLIITH project is RMB 8.6 billion, with a planned land area of 1,800 mu and a planned PLA production capacity of 350,000 tons.

PLIITH Biotechnology Co., Ltd., founded in 2021 as a joint venture with the Changchun Institute of Applied Chemistry of Chinese Academy of Sciences, has a total investment of RMB 8.6 billion, with a planned land are of 1,800 mu and a planned PLA production capacity of 350,000 tons. Among these plans, the first phase of a 75,000 tons/year lactic acid and 50,000 tons/year PLA smart factory project officially started construction in Wuhu City, Anhui Province, in 2021 and is currently undergoing on-load testing and commissioning.

PLIITH focuses on the research, development, production, sales, and technical services of bio-based materials, striving to become a global leader in PLA materials.

PLIITH Biotechnology Co., Ltd. is an enterprise that specializes in the technology development, production and processing, and industrial promotion of high-purity lactic acid, lactide, and PLA. The Company aims to create a comprehensive chain layout from "deep processing of agricultural products - microbial fermentation - fine chemical engineering - high molecular new materials - new material application." The Company focuses on the research, development, production, sales, and technical services of biobased materials, committed to becoming a global leader in polylactic acid (PLA) materials.

PLIITH's PLA project has advanced the synthesis and manufacturing capabilities of lactide and PLA, as well as the process equipment, constructing a new-generation pilot production line. This has enabled the completion of standard compliance testing and industry certification for the PLIITH PLA pilot materials.

The PLIITH's PLA project, based on two decades of dedicated research by the Changchun Institute of Applied Chemistry of Chinese Academy of Sciences, has overcome the synthesis and manufacturing processes and equipment capabilities for lactide and PLA. It has solved a series of technological challenges including dehydration, oligomerization, cracking, distillation, polymerization, and degassing. Using the experience gained from ton-scale production, it has constructed a new-generation pilot production line and completed the standard compliance testing and industry certification of PLIITH's PLA pilot materials.

PLIITH adheres to the development philosophy of "Green, Innovative, Collaborative and Win-Win."

PLIITH will always uphold the development philosophy of "Green, Innovative, Collaborative and Win-Win", working together with industry peers in the biodegradable materials supply chain to contribute to the healthy development of the biodegradable materials industry and fulfill its mission of creating a naturally beautiful environment.