Polylactic Acid Modified Materials

Kinpoly Advanced Materials Co., Ltd.

For more information er inquiry, please click to Kinpoly's website

PLIITH's Modified Materials Division is mainly engaged in the modification research, application development, production, and sales of biobased and biodegradable materials, dedicated to providing customers with high-performance and functional green environmental protection materials solutions.

Polylactic Acid (PLA): Derived from renewable biomass materials and completely degradable into water and CO2, fully meeting the requirements of green, low-carbon, sustainable economic development. However, PLA has inherent limitations such as brittleness, low melt strength, poor heat resistance, and uncontrollable degradation rate, which greatly limit its performance and market competitiveness. PLIITH's Modified Materials Division has thoroughly overcome these limitations, effectively expanding PLA applications. Currently, Kinpoly uses PLA, PBS, PBAT, and PHAs as raw materials and has developed a series of product solutions, primarily including straws, cutlery, films/membranes, sheets/blister packaging, 3D printing, and injection-molded products, all meeting the biodegradation requirements of ASTM D6400, EN13432, and GB/T19277.

Solutions

Customized biodegradable material solutions based on customer requirements and application scenarios.

Straw Product Series

|

Product line |

Product grades |

Maximum use temperature |

Product characteristics |

|

Straight straw |

Cold drink straw H8000-1H |

80℃ |

Completely biodegradable Balanced rigidity and toughness Freezing Resistance: ice-water mixture for 5 minutes, no cracking Freezing Resistance: frozen at -15℃ for 4h, no cracking Little smoke and odor Low pipe breaking frequency |

|

Heat-resistant straw H8000-1A |

70℃ |

||

|

Crystalline Heat-Resistant H8000-1G |

50℃ |

||

|

Bent Straws |

Heat-Resistant Straw H8000-1D |

65℃ |

|

|

Cold Drink Straw H8000-1E |

50℃ |

Straight straw

Bent Straws

Injection molding product series

|

Product line |

Product grades |

Description |

Maximum use temperature |

Product characteristics |

|

Cutlery |

H8000-2D |

Annealed crystalline heat-resistant |

90℃ |

High fluidity, balanced rigidity and toughness |

|

H8000-2C |

Biomass composite materials |

90℃ |

High fluidity, balanced rigidity and toughness |

|

|

Thin-wall injection molding |

H8000 |

Heat-resistant materials |

90℃ |

Ultra high liquidity, balanced rigidity and toughness |

|

Durable products |

H8000-2H |

Hotel supplies |

70℃ |

Balanced strength and durability |

|

H8000-2P |

Electronics accessories |

70℃ |

Balanced strength and durability |

|

|

H8000-2A |

Melamine alternatives |

120℃ |

Balanced strength and durability |

Disposable knives, forks, spoons

Disposable bamboo powder composite products

lunch box

Yogurt cup

Vacuum cleaner buckle

Hotel storage box

Thin film product series

|

|

M1000 |

M2000 |

M5000-5C |

M5000-20B |

|

Melt index(g/10min) |

2-4 |

2-4 |

1-3 |

2-4 |

|

Longitudinal tensile strength(MPa) |

≥18 |

≥23 |

≥23 |

≥23 |

|

Longitudinal elongation at break(%) |

≥350 |

≥350 |

≥400 |

≥400 |

|

Degradability, |

Home composting, industrial composting |

Industrial composting |

Industrial composting |

Industrial composting |

|

Stiffness |

Good |

Excellent |

Excellent |

Excellent |

|

Aging resistance (double 60 aging for 12 days) |

Good |

Excellent |

Excellent |

Excellent |

|

Colour |

True qualities |

True qualities |

Raw white |

Transparent |

|

Application area |

Milk tea bags, supermarket shopping bags, garbage bags, pet poop bags, industrial dust covers |

|||

Supermarket shopping bag

Supermarket shopping bag

Milk tea bag

Bags

Blister product series

|

|

H8000-3A |

H8000-3B |

H8000-3C |

H8000-3E |

H8000-3K |

|

Material |

PLA |

PLA |

PLA/Talc |

PLA/Talc |

PLA/Talc |

|

Density(g/cm3) |

1.25 |

1.25 |

1.35 |

1.40 |

1.40 |

|

Transparency, |

High transparency |

Transparent |

Non-transparent |

Non-transparent |

Non-transparent |

|

Maximum operating temperature(℃) |

50 |

100 |

120(Microwavable) |

90 |

50 |

|

Blister mold temperature(℃) |

15~35 |

90~110 |

90~110 |

90~110 |

90~110 |

|

Application |

Cards, lunch boxes, trays, plates, cups and other food packaging products |

||||

|

Other features |

scraps can be processed repeatedly, product wall thickness is uniform, deep-drawn products can be formed, twin-screw extrusion sheets are recommended |

||||

Cup cover

Bowl

Lunch box

Lunch box

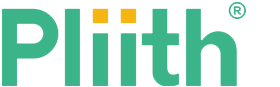

3D Printing Product Series

|

Granular material grade |

Notes |

Special Attributes |

|

H8000-5A |

Translucent |

Good gloss and transparency |

|

H8000-5G |

High toughness |

High brightness, high gloss, high toughness |

|

H8000-5B |

Super toughness |

High impact resistance, high elongation at break, high bonding strength |

|

H8000-5Y |

Matte |

Significant matte effect, excellent peeling performance |

|

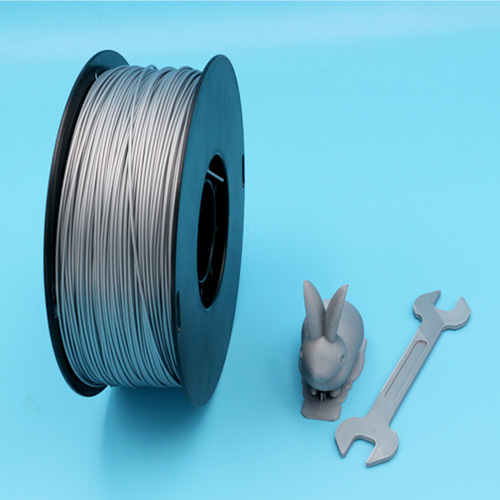

H8000-5J |

Imitation metal color |

Strong metallic luster texture (silver, copper) |

|

H8000-5S |

Silk color |

Strong silk texture, excellent mechanical properties |

|

H8000-5F |

Fast printing |

High-speed printing, no warping of parts |

|

H8000-5H |

High heat resistance |

Excellent heat resistance, no deformation at high temperature |

|

H8000-5LW |

Lightweight |

Density as low as 0.5-0.9g/cm3, suitable for models of aircraft, ships, etc. |

Silk color

Metallic silver

Silk gold

Certification and test report

Biodegradable certification

Biodegradable certification

Biodegradable certification

National standard GB 4806.7 food safety test report